A novel beam diagnostic instrument developed by researchers at the University of Liverpool’s QUASAR Group is now fully operational within the Large Hadron Collider (LHC), the world’s most powerful particle accelerator. This marks a significant advancement in the field of accelerator physics, enabling more precise, non-invasive monitoring of high-energy particle beams.

The Challenge of Beam Measurement

Measuring the properties of particle beams at extreme energies is a complex task. Traditional methods often disrupt the beams themselves, compromising the accuracy of experiments. The new device, known as the Beam Gas Curtain (BGC) monitor, overcomes this challenge by providing continuous, non-invasive measurements throughout the LHC’s operational cycle.

How the Beam Gas Curtain Works

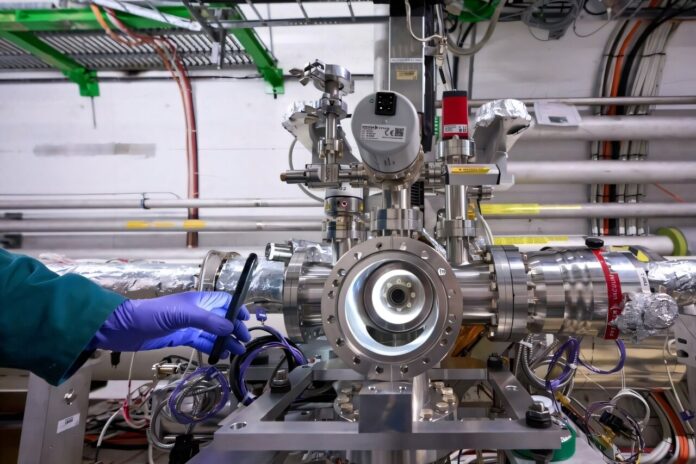

The BGC monitor utilizes an ultra-thin sheet of neon gas—a “curtain”—that interacts with the circulating proton or lead ion beams. This interaction produces faint flashes of fluorescence light, which are captured by a sophisticated optical system. By analyzing these flashes, scientists can determine the beam’s size and quality with unprecedented precision, from the initial injection stage (450 GeV) up to the LHC’s peak energy (6.8 TeV).

Years of Development Culminate in Success

The technology behind the BGC monitor was conceived and refined over a decade within the QUASAR Group. Led by Professor Carsten P. Welsch, the team overcame numerous technical hurdles, including vacuum compatibility, optical design, and software integration. The device underwent extensive testing at the Cockcroft Institute before its installation at CERN.

Validated Performance and Future Impact

The BGC monitor’s performance has exceeded expectations, delivering high-precision measurements for both proton and heavy-ion beams. Independent validation confirms that the results closely align with established LHC diagnostics, such as the Beam Synchrotron Radiation Telescope and emittance scans at the ATLAS and CMS experiments.

The approval of the BGC monitor for continuous operation (~2,000 hours per year) opens the door for similar systems in other major research facilities. This includes the European Spallation Source in Sweden, the Electron Ion Collider in the U.S., and even medical accelerator applications.

“This achievement shows how university-based innovation can directly shape the tools that keep the world’s largest scientific instruments running,” said Professor Welsch. “It is a very proud moment for Liverpool and for all the students and researchers who contributed to this remarkable journey.”

The BGC monitor represents a significant step forward in accelerator technology, enabling more precise control and monitoring of particle beams at the world’s leading scientific facilities